Box Plant Balers

The generation of corrugated scrap and how to handle it has been an issue since the first corrugated box was made. American Baler is a leader in its design and engineering for this industry. From the early designs of our box plant balers (early 50’s) thru the 70’s and 80’s with our 10,000, 12,000 and 13,000 series to our current PAC and 29N designs we have been an industry leader.

The PAC baler with three different hopper sizes was designed to handle light trim and shredded material producing export quality bales. The 29N series was engineered to handle heavier board trim and shredded materials and is available with or without a shear blade.

Our Box Plant Balers That Apply To This Market Include

Waste Baler for Printers / Converters

For years Printers / Converters have been baling shreds, edge trim, signatures, slab waste, tissue logs and cookies, and other grades and American Baler has manufactured waste balers for each application. The PAC series balers are used for light trim and shredded OCC and paper. Our 29N and 42W Series balers handle these Printers / Converters grades with additional ram force and larger feed openings. For low volume Printers / Converters the manual tie PW3560 and W409D auto-tie two ram baler are ideal while high volume Printers / Converters may want to look at the 43HS Series.

Our Waste Baler Models For The Printer / Converters Market Include

American Baler also builds 2 ram waste baler models with the following features that are suitable for most MSW baling applications.

If you are baling MSW American Baler will have a two ram waste baler model that will meet your needs. Plus we offer the best baler warranty in the business!

Two Ram Waste Baler Features

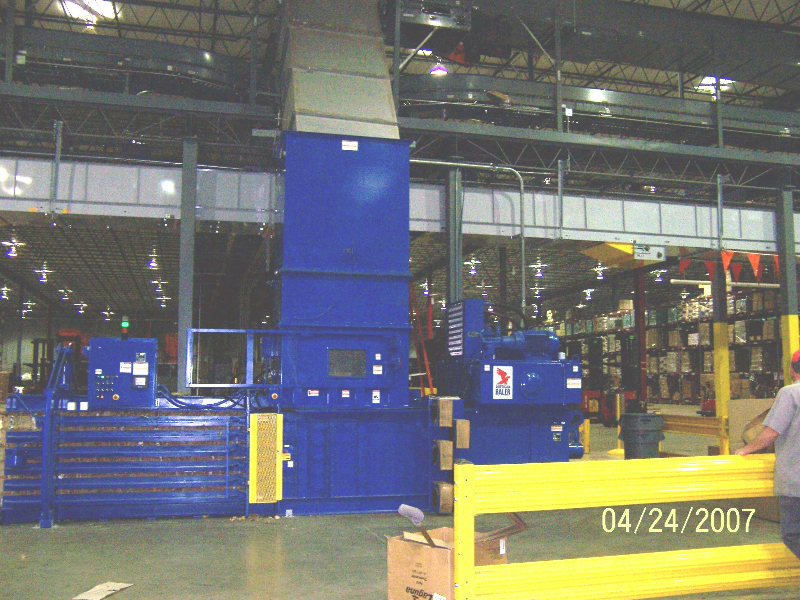

Distribution Centers

Distribution Centers are an industry where the majority of product being baled is set-up cardboard cartons and it is important that the balers used in this environment have a large feed opening and fast ram cycle to keep up with the steady stream of cartons to the baler. American Baler offers several models with feed openings up to 75″ x 48″ and no-load cycle times as quick as 9.5 seconds. Many of these models produce export quality bales that will allow customers the ability to maximize load weights and keep their shipping cost per ton to a minimum.

Our balers that apply to the Distribution Centers market are:

MRF’s

Variety! A wide variety of recyclable materials from the waste stream are sorted and baled at MRF’s (material recycling facilities) around the world every day. Our MRF customers need to be competitive in the marketplace and American Baler offers a diverse and time tested product mix for this application. Utilizing American Baler’s unique single-ram tension control system, our balers can easily and quickly adapt to most grades providing customers with ease of transition and high quality bales.

Our Balers That Apply To The MRF’s Market Include

Metal Baler for Non-Ferrous

Baling non-ferrous metals requires a heavy duty metal baler with high compressing and shearing force and a fully lined charge box and bale chamber. American Baler manufactures narrow box and wide box two-ram auto-tie balers for baling non-ferrous metals as well as the manual-tie Model NF4560-1050 closed-door baler. By offering this wide variety of feed opening sizes, main ram compression forces and ram speeds we generally have a metal baler that’s ideal for our low volume and high volume customers. Since non-ferrous metals are highly abrasive we use replaceable Hardox 500 liner plate in high wear areas and tool steel shear blades for longer life.

Our Metal Baler Models That Apply To The Non-Ferrous Market Include

American Baler builds two ram metal baler models with the following features that are suitable for most non-ferrous metal baling applications.

Metal Baler Features

If you are non-ferrous metal recycler American Baler will have a two ram metal baler model that will meet your needs. Plus we offer the best baler warranty in the business!

Recycling Baler for Recycler / Broker

Throughout its history American Baler has focused on providing recycling baler / paper balers to Recycler / Brokers. The expertise and knowledge of our employees and dealers have given us the insight to guide Recycler / Brokers to the appropriate baler / equipment for their needs. American Baler offers both extrusion and Two Ram auto-tie balers with different feed opening sizes, cylinder options and power units. All are capable of baling a variety of fiber and non-fiber products.

Our Recycling Baler Models That Apply To The Recycler / Brokers Market Include

American Baler builds two ram recycling baler models with the following features that are suitable for most OCC, paper, plastic and non-ferrous metal baling applications.

If you are a paper, plastic and/or non-ferrous metal recycler American Baler will have a two ram recycling baler model that will meet your needs. Plus we offer the best baler warranty in the business!

Our Recycling Baler Features

Document Destruction

In the Document Destruction industry bale integrity is very important. Bales of shredded documents must be tight and secure for handling and shipping to the mill. Our signature PAC Series balers have for years been a dependable favorite with many members of the National Association for Information Destruction. These PAC balers are available with four different power units and three feed opening sizes to meet most hourly production requirements. We also offer several higher capacity models for larger facilities that operate both mobile and plant shredder systems.

Our Balers That Apply To The Document Destruction Market Include

Municipal

Municipal recycling programs provide recycling opportunities for people living in small cities, counties and rural areas. American Baler works with these Municipal entities to provide dependable low cost balers for these low production facilities. These balers will handle cardboard, newspaper, mixed paper, plastic containers and cans and are designed to be hand-fed, conveyor-fed or fed with a small bucket loader.

Our Balers That Apply To The Municipal Market Include

Model PW3560 42W Series 43HS Series Narrow & Wide Box Two Ram Balers

Baler Cardboard

American Baler builds single ram baler cardboard with the following features that are suitable for most paper recycling applications.

If you are a paper or plastic recycler American Baler will have a single ram baler cardboard models that will meet your needs. Plus we offer the best baler warranty in the business!

Baler Cardboard Features

Misc

American Baler has extensive experience designing and building special balers for unusual materials such as begasse, mineral wool, chopped hay, etc.

NOTE: Please consult with factory over any customized designs.

Our Balers That Are Generally Used In Misc. Markets Include

Textile Clothing Baler

Textile (Clothing) baling generally refers to the baling of used clothing that will be shipped to developing countries for re-use. This is a growing market that requires dense bales without damaging the clothing during baling. American Baler has for years used the PAC4029 no-shear baler with special features for this clothing application. The clothing bales from the PAC4029 load well into sea containers, generally resulting in a lower shipping cost per ton. The auto-tie feature increases production and eliminates a majority of operator involvement.

Our PAC Series balers are well suited for the Textile Market.